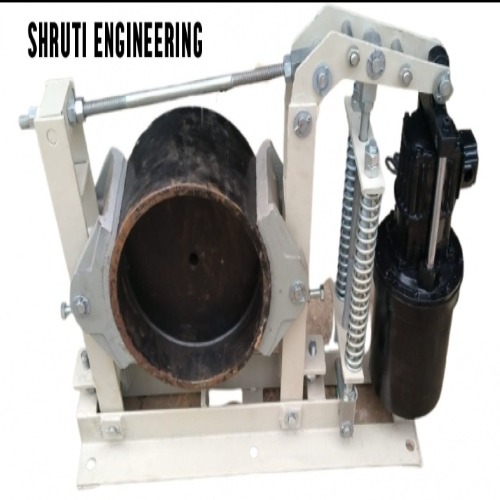

440 Electro Hydraulic Thrustor

440 Electro Hydraulic Thrustor Specification

- Noise Level

- Low

- Usage & Applications

- Electro Hydraulic Thruster Brake Mechanisms, Hoists, Conveyors, EOT Cranes, Lifts, Material Handling Equipment

- Features

- Corrosion Resistant, Maintenance Free, Sturdy Design, High Efficiency

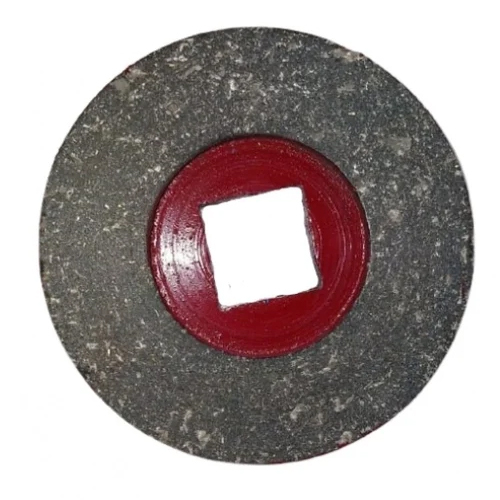

- Part Type

- Thrustor

- Mounting Type

- Flange Mounted

- Brake Type

- Brake

- Size

- 440

- Material

- MS

- Pattern Material

- Cast Iron

- Surface Finish

- Paint Coated

- Standard

- IS 3188

- Protection Class

- IP 55

- Weight

- 21 kg

- Duty Cycle

- S1 Continuous

- Operating Temperature Range

- -10°C to +50°C

- Insulation Class

- Class F

- Stroke Length

- 51 mm

- Voltage

- 415 V AC

- Ambient Humidity

- Up to 90% RH non-condensing

- Rated Thrust

- 18 kgf

- Frequency

- 50 Hz

- Oil Capacity

- 2.2 Ltr

440 Electro Hydraulic Thrustor Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 3 Days

About 440 Electro Hydraulic Thrustor

440V Electro Hydraulic Thrustor Description

The 440V Electro Hydraulic Thrustor is a high-performance actuator designed to operate industrial brake systems, such as thruster drum brakes used in EOT cranes, hoists, conveyors, and material handling equipment. It converts electrical energy into linear mechanical force, ensuring smooth, efficient, and controlled braking operations.

Built with a rugged cast iron housing, the thrustor is designed for continuous duty under harsh industrial conditions. It operates on 440V AC supply and provides reliable thrust force to release or apply brakes precisely and safely.

The oil-immersed design ensures high efficiency, minimal wear, and long service life, while the maintenance-free operation makes it ideal for industrial environments requiring dependable performance.

High-Performance and Reliability

Built for continuous operation (S1 duty cycle), the 440 Electro Hydraulic Thrustor delivers unwavering linear thrust, crucial for material handling equipment, cranes, and industrial elevators. Its sturdy cast iron body ensures robust performance and high efficiency, minimizing downtime and enhancing operational consistency.

Designed for Harsh Environments

With an ambient temperature range from -10C to +50C, Class F insulation, IP 55 protection, and a corrosion-resistant finish, this thrustor is suitable for challenging workplaces prone to dust, moisture, or high humidity. Its low-noise operation and maintenance-free design increase workplace safety and comfort.

Versatile Applications

Ideal for integration into thruster brake mechanisms and as an actuator in hoists, conveyors, EOT cranes, and lifts, the 440 size model ensures compatibility with a range of standard industrial systems, following IS 3188 safety and quality standards.

FAQs of 440 Electro Hydraulic Thrustor:

Q: How is the 440 Electro Hydraulic Thrustor typically installed and used?

A: This thrustor is flange-mounted, making it easy to integrate directly into brake mechanisms, hoisting equipment, and conveyor systems. Its primary function is to provide controlled, linear thrust in electro-hydraulic braking or actuation assemblies.Q: What are the main benefits of using this thrustor in material handling applications?

A: The device offers high efficiency, maintenance-free operation, and reliable performance even under continuous-duty conditions. Its robust design and corrosion-resistant coating contribute to its longevity and trouble-free operation in challenging environments.Q: When should the thrustor oil level be checked or refilled?

A: Although designed for maintenance-free use, its advisable to periodically check the oil capacity (2.2 liters) during scheduled equipment maintenance to ensure optimal hydraulic performance and extended service life.Q: Where is this thrustor most effectively applied?

A: This model is best suited for use in electric overhead travelling (EOT) cranes, lifts, hoists, conveyors, and industrial braking systems where consistent and powerful linear thrust is required for safe and reliable machine operation.Q: What insulation and protection ratings does the thrustor provide?

A: The 440 Electro Hydraulic Thrustor utilizes Class F insulation, supporting higher operating temperatures, and an IP 55 protection class, safeguarding against dust ingress and water jets, making it ideal for humid or dusty industrial environments.Q: How does the thrustor perform under high humidity or fluctuating temperatures?

A: Engineered for tough conditions, it operates effectively at ambient humidity levels up to 90% RH (non-condensing) and temperatures between -10C and +50C, ensuring reliability in diverse climates and workspaces.Q: What standards and materials are used in the construction of this thrustor?

A: Manufactured according to IS 3188 standards, the thrustor features a cast iron body with paint coating for corrosion resistance, while internal components utilize high-quality MS (mild steel) to ensure durability and stable operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in THRUSTER BRAKE Category

Cast Iron Electro Hydraulic Thruster In Indore , For E

Price 11580.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Iron

Size : Standard

Warranty : 1 Year

Usage & Applications : Industrial

Electro Hydraulic Thruster In Mumbai In Mumbai, For Eot Crane

Price 12250.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast iron

Size : Standard

Warranty : 1 Year

Usage & Applications : Industrial

Cast Iron THRUSTER BRAKE DRUM IN PUNE , For

Price 3900.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast iron

Size : Standard

Warranty : 1 Year

Usage & Applications : Industrial

THRUSTER BRAKE DRUM COUPLING IN RAJKOT , Cast Iron

Price 9570.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast iron

Size : Standard

Warranty : 1 Year

Usage & Applications : Industrial

|

SHRUTI ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese